RECHERCHE PAR CATEGORIES

RECHERCHE PAR INSPIRATIONS

- Shock absorbers

- Thermal bands

- Aluminum boxes

- Rear curls

- Bubbles

- Turn signals

- Commodos

- Meters

- Rear shells

- Exhaust

- Rear lights

- Air filters

- Forks

- Wardrobe

- Handlebars

- Brake and clutch levers

- Side plates

- Handles

- Headlights

- Footrest

- Tanks

- Mirrors

- Stool

- Silent

- Fork bellows

- Insurance supports

- License plate supports

- Shock absorbers

- Thermal bands

- Aluminum boxes

- Rear loops

- Bubbles

- Turn signals

- Commodos

- Meters

- Rear shells

- Swine

- Rear lights

- Air filters

- Forks

- Wardrobe

- Handlebars

- Brake and clutch levers

- Side plates

- Handles

- Headlights

- Footrest

- Tanks

- Mirrors

- Stool

- Silent

- Fork bellows

- Insurance supports

- License plate supports

- Shock absorbers

- Thermal bands

- Aluminum boxes

- Rear curls

- Bubbles

- Turn signals

- Commodos

- Meters

- Rear shells

- Exhaust

- Rear lights

- Air filters

- Forks

- Wardrobe

- Handlebars

- Brake and clutch levers

- Side plates

- Handles

- Headlights

- Footrest

- Tanks

- Mirrors

- Stool

- Silent

- Fork bellows

- Insurance supports

- License plate supports

- Shock absorbers

- Thermal bands

- Aluminum boxes

- Rear loops

- Bubbles

- Turn signals

- Commodos

- Meters

- Rear shells

- Swine

- Rear lights

- Air filters

- Forks

- Wardrobe

- Handlebars

- Brake and clutch levers

- Side plates

- Handles

- Headlights

- Footrest

- Tanks

- Mirrors

- Stool

- Silent

- Fork bellows

- Insurance supports

- License plate supports

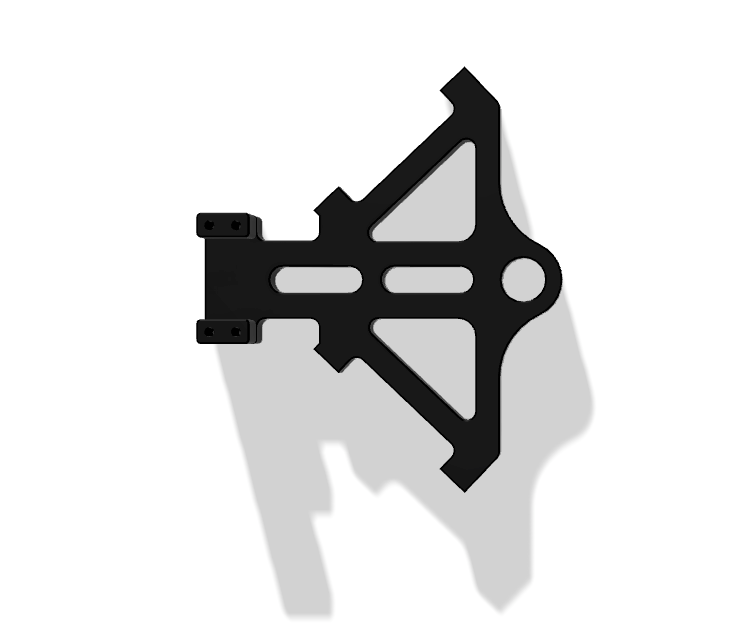

Brake stirrup

The motorcycle brake brake is an essential element of the braking system. When the driver activates the brakes, he plays an important role in slowing down and stopping the motorcycle.

The stirrup, often fixed at the axis of the wheel, houses the brake pads and works with the brake disc to provide the necessary friction for braking. Brake calipers are made in robust materials such as aluminum or steel and are available in a variety of shapes, ranging from fixed calipers to floating or sliding types.

The calipers are classified into two types: simple piston and multiple multiple. Simple piston calipers have a single piston on one side of the rotor which presss the brake pads against the disc to slow down the wheel.

Multipist calipers, such as double piston or four piston models, have many pistons on each side of the rotor. This design allows a more uniform pressure distribution, thus improving the efficiency and braking performance.

The calipers work hydraulically. When the driver activates the brake lever, the brake fluid circulates in the brake pipes, pushing the pistons inside the caliper to press the platelets against the rotor. This action generates friction, effectively slowing down the motorcycle.

The radial brake caliper is an advanced version of braking technology. Unlike standard calipers, radial calipers are placed in parallel with the axis of the wheel, improving braking performance by optimizing the lever and reducing flexion during braking.

It offers precise and reactive control at the driver's braking input, as well as a more direct strength distribution and a better braking feeling.

Motorcycle brake calipers vary in design, size and complexity, and are suitable for certain brands, models and planned uses. Whatever their differences, it is a critical security component, guaranteeing constant braking performance and control in a wide range of driving conditions and styles.

The stirrup, often fixed at the axis of the wheel, houses the brake pads and works with the brake disc to provide the necessary friction for braking. Brake calipers are made in robust materials such as aluminum or steel and are available in a variety of shapes, ranging from fixed calipers to floating or sliding types.

The calipers are classified into two types: simple piston and multiple multiple. Simple piston calipers have a single piston on one side of the rotor which presss the brake pads against the disc to slow down the wheel.

Multipist calipers, such as double piston or four piston models, have many pistons on each side of the rotor. This design allows a more uniform pressure distribution, thus improving the efficiency and braking performance.

The calipers work hydraulically. When the driver activates the brake lever, the brake fluid circulates in the brake pipes, pushing the pistons inside the caliper to press the platelets against the rotor. This action generates friction, effectively slowing down the motorcycle.

The radial brake caliper is an advanced version of braking technology. Unlike standard calipers, radial calipers are placed in parallel with the axis of the wheel, improving braking performance by optimizing the lever and reducing flexion during braking.

It offers precise and reactive control at the driver's braking input, as well as a more direct strength distribution and a better braking feeling.

Motorcycle brake calipers vary in design, size and complexity, and are suitable for certain brands, models and planned uses. Whatever their differences, it is a critical security component, guaranteeing constant braking performance and control in a wide range of driving conditions and styles.